Fosber Corrugated Board Lithipa Tse Sethang

Lithipa tse chitja tsa pampiri tse entsoeng ka sekontiri se entsoeng ka tungsten carbide le cobalt powder metallurgy li na le boima bo phahameng le ho hanyetsa ho roala, 'me ka nako e ts'oanang li na le ho hanyetsa mocheso o motle le ho hanyetsa kutu, e le hore lithipa li sebelisoe haholo ha ho sehoa lik'hateboto.

Ka ho fetola karo-karolelano ea tungsten carbide le cobalt le boholo ba karoloana ea tungsten carbide phofo, re fumana li-carbide tse entsoeng ka samente tse nang le thepa e fapaneng ho finyella litlhoko tsa bareki ba fapaneng.

Khamphani ea rona e na le lilemo tse fetang 20 tsa nalane ea tlhahiso ea lithipa tse betliloeng tsa tungsten carbide, e sebetsanang le tlhahiso ea lithipa tse pota-potileng tsa pampiri ea tungsten carbide le lithipa tse fapaneng tsa carbide.

Ho feta halofo ea lihlahisoa li romelloa Europe, United States le linaheng tse ling tse tsoetseng pele le libaka.Ts'ebetso ea sehlahisoa e kopana ka botlalo le litlhoko tse tiileng tsa lisebelisoa tse fapaneng tsa lebelo le holimo.Boleng ba sehlahisoa bo boemong bo ka sehloohong likarolong tsa 'maraka oa lisebelisoa tsa indasteri ea malapeng le ea linaheng tse ling.

Sepheo sa k'hamphani ea rona ke ho ba morekisi ea hloahloa ka ho fetisisa, ea boleng bo holimo, le morekisi e moholo ka ho fetisisa oa lithipa tse betliloeng tsa tšepe ea tungsten.

| Kereiti | Boholo ba lijo-thollo | Botenya | Ho thatafala | TRS(N/mm²) | E loketse ho Seha |

| g/cm³ | HRA | ||||

| ZT20U | Sub-fine | 14.35-14.5 | 91.4-91.8 | 3200 | Boto e entsoeng ka masenke, fiber ea lik'hemik'hale, polasetiki, letlalo |

| ZT26U | Sub-fine | 14-14.1 | 90.4-90.8 | 3500 | Boto e entsoeng ka masenke, likotoana tsa lipalo tsa Battery |

| ZT30U | Sub-fine | 13.85-14 | 89.7-90.2 | 3200 | Letlapa la pampiri |

| Lintlha No | OD (mm) | ID (mm) | T (mm) | masoba(mm) | E fumaneha bakeng sa Mochini |

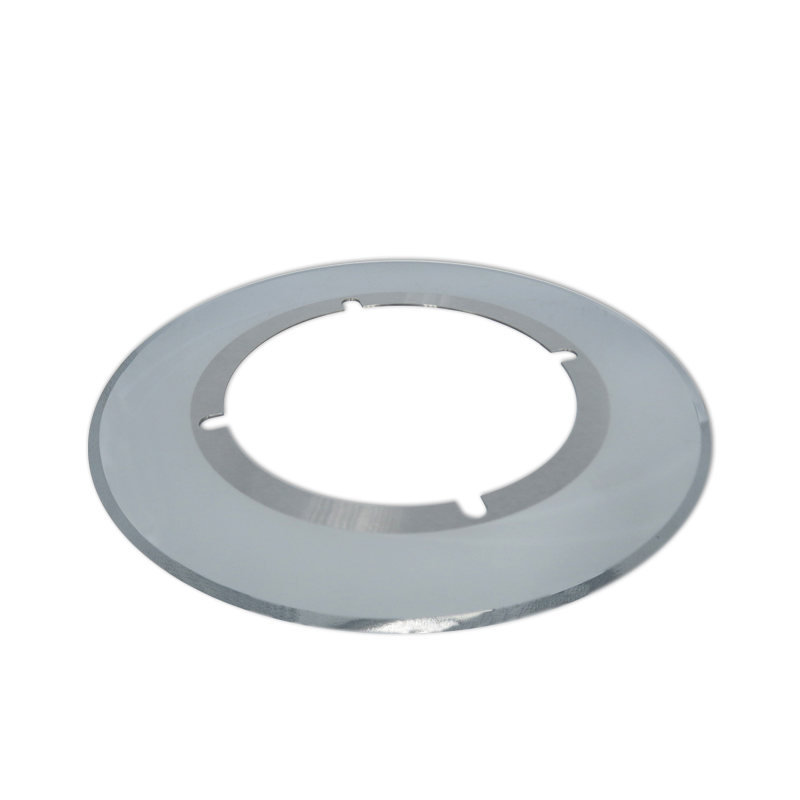

| 1 | 230 | 110 | 1.1 | φ9*6 masoba | FOSBER |

| 2 | 230 | 135 | 1.1 | 4 linotlolo tsa bohlokoa | FOSBER |

| 3 | 220 | 115 | 1 | φ9*3 masoba | AGNATI |

| 4 | 240 | 32 | 1.2 | φ8.5*2 masoba | BHS |

| 5 | 240 | 115 | 1 | φ9*3 masoba | AGNATI |

| 6 | 250 | 150 | 0.8 | PETROSE | |

| 7 | 257 | 135 | 1.1 | FOSBER | |

| 8 | 260 | 112 | 1.5 | φ11*6 masoba | ORANDA |

| 9 | 260 | 140 | 1.5 | ISOWA | |

| 10 | 260 | 168.3 | 1.2 | φ10.5*8 masoba | MARQUIP |

| 11 | 270 | 168.3 | 1.5 | φ10.5*8 masoba | HSEIH |

| 12 | 270 | 140 | 1.3 | φ11*6 masoba | VATANMAKEINA |

| 13 | 270 | 170 | 1.3 | φ10.5*8 masoba | |

| 14 | 280 | 160 | 1 | φ7.5 * 6 masoba | MITSUBISHI |

| 15 | 280 | 202 | 1.4 | φ8*6 masoba | MITSUBISHI |

| 16 | 291 | 203 | 1.1 | φ8.5*6 masoba | FOSBER |

| 17 | 300 | 112 | 1.2 | φ11*6 masoba | TCY |

| Lintlha No | OD (mm) | ID (mm) | T (mm) | Likoti |

| 1 | 200 | 122 | 1.2 | |

| 2 | 210 | 110 | 1.5 | |

| 3 | 210 | 122 | 1.3 | |

| 4 | 230 | 110 | 1.3 | |

| 5 | 230 | 130 | 1.5 | |

| 6 | 250 | 105 | 1.5 | φ11mm*6 masoba |

| 7 | 250 | 140 | 1.5 | |

| 8 | 260 | 112 | 1.5 | φ11mm*6 masoba |

| 9 | 260 | 114 | 1.6 | φ11mm*8 masoba |

| 10 | 260 | 140 | 1.5 | |

| 11 | 260 | 158 | 1.5 | φ11mm*8 masoba |

| 12 | 260 | 112 | 1.4 | φ11mm*6 masoba |

| 13 | 260 | 158 | 1.5 | φ9.2mm*3 masoba |

| 14 | 260 | 168.3 | 1.6 | φ10.5mm*8 masoba |

| 15 | 260 | 170 | 1.5 | φ9mm*8 masoba |

| 16 | 265 | 112 | 1.4 | φ11mm*6 masoba |

| 17 | 265 | 170 | 1.5 | φ10.5mm*8 masoba |

| 18 | 270 | 168 | 1.5 | φ10.5mm*8 masoba |

| 19 | 270 | 168.3 | 1.5 | φ10.5mm*8 masoba |

| 20 | 270 | 170 | 1.6 | φ10.5mm*8 masoba |

| 21 | 280 | 168 | 1.6 | φ12mm*8 masoba |

| 22 | 290 | 112 | 1.5 | φ12mm*6 masoba |

| 23 | 290 | 168 | 1.5/1.6 | φ12mm*6 masoba |

| 24 | 300 | 112 | 1.5 | φ11mm*6 masoba |

Tlhahlobo ea mathata a tloaelehileng a lithipa tsa borata tsa masenke

(Eseng: mathata ohle ao re buisaneng ka ona bakeng sa lithipa tse tšoanelehang)

Q1 Hobaneng ho na le nako e khuts'oane ea ho sebetsa ea boto e sehiloeng ka lithipa?

A : Na boholo ba lijo-thollo tsa lebili le silang bo nepahetse?

Mahoashe a boholo ba lijo-thollo tsa lebili le silang etsa nako e khuts'oane ea ho sebetsa ea lithipa

Q2 Ke hobane'ng ha likarolo tsa liboto tsa masenke li khaotsoe ka lithipa tse nang le sekoti le sekoti?

A: Ka kopo, sheba ntlha e sehang ea lithipa tsa hau, na moeli o sehang o na le kelello e lekaneng?Kapa haeba boto e entsoeng ka masenke e le metsi haholo?

Q3 Lithipa tse robehileng

A: Kopano e sa nepahalang (mohlala, poleiti ea flange e holofetseng; screwing e sa nepahalang) e tla etsa hore mahare a robehe ka potlako, ho ts'oaroa hofe kapa hofe ha mahare ho thibetsoe ka thata nakong ea ts'ebetso;

Mabili a sila a sa tsitsang a pshatla lithipa, ka kopo sheba hore na mabili a sila a sebetsa joang.

Ho ts'oara kapa ho otla ka lintho tse ling tse thata.

Ho thula ka kotsi dithipa

Q4 Chips ka ho itšeha ka mor'a ho sila.

A: Mabili a sila a sa tsitsang a ka baka bothata bona, esita le ho pshatla lithipa , Ho otla ha lintho tse thata ho ka 'na ha etsa hore li-chips li sehe moeli hape.

Q5 Ke hobane'ng ha moeli oa boto ea masenke o sa otloloha?

A: Matla a ke keng a lekanngoa a lithipa bakeng sa boto ea masenke e nang le sekhahla se phahameng.

FAQ mabapi le thekiso ea pele le ka mor'a thekiso

P: A na nka fumana lisampole tsa liteko tsa mahala?

A: E, haeba u na le tlhoko e hlakileng, re ka fana ka lisampole tsa mahala bakeng sa tlhahlobo.

Q: Ho thoe'ng ka nako ea pele?

A: Re na le litlhaloso tse tloaelehileng setokong, 'me li ka romelloa matsatsing a mararo ka mor'a ho netefatsa konteraka.

P: A na u ka fana ka lithupa tsa tšepe?

E, re na le bafani ba thepa ba sebelitseng ka lilemo tse ngata, 'me ba ka u fa lithupa tsa stell scraper tsa boleng bo holimo, tsa theko e tlase.

Q: Na fektheri ea hau e ka fana ka tlhahiso ea OEM?

A: E, haeba theko ea hau e lumellana le litlhoko, re ka u etsetsa sephutheloana ho latela litlhoko tsa hau.

Q: Na u netefatsa boleng?

Ee, re na le lits'ebeletso tse netefalitsoeng tsa ho lata lihlahisoa tse rekisitsoeng.Haeba u na le lipotso, ka kopo ikutloe u lokolohile ho ikopanya le basebetsi ba rona ba thekiso.U tla fumana litšebeletso tse khotsofatsang ka mor'a thekiso nakong ea lihora tse 24.